Technology 6

The Good, Bad and Ugly of the IoT

The Internet of Things, shortened as IoT, could possibly be the mascot of the appropriately named Industry 4.0. However, according to high-profile technologists such as Don DeLoach, it could be a double-edged sword.

On serious reflection, the first revolution is a slovenly edition of the current revolution. The Industry 4.0 is a blessing and disaster in equal measure.

The Good

For starters, the IoT is a technological development proposed by the Internet of Things Institute (IoTI). It will enhance our daily activities with Internet connection, facilitating data communications.

First, the Internet of Things bodes well for the latter-day global challenges. How? This includes global warming and strained resources? Over the next two decades, it’s predicted that the global population will increase by 2 billion people. To feed the extra mouths, the farm output has the ability to increase thanks to innovation enabled by the IoT. What’s more, farmers will cash in on better agricultural prospects.

Second, IoT oriented technology has the power to improve global security, enhance healthcare services, and boost the global bread baskets. The Internet of Things has brought about advanced security systems. For instance, the gunfire locator; by using sensors such as acoustic and optical and via geographic information system, this can pinpoint the location of a gunfire incident. These security apparatus can be applied in urban centers to help standby security personnel act and react to such gunfire.

Third, improving care services; the technology breakthrough facilitated by the IoT can be handy in overseeing the welfare of old people and enable medical professionals to get in touch with and distantly liaise with the sick.

FYI, the IoT sector is still in its formative stage. However, it will develop like the way the introduction of smartphones in the market has seen an influx of apps.

The Bad and the Ugly

The Internet of Things Institute has a flip side. The first one is cyber insecurity. There are cyber attacks taking advantage of the loopholes in the IoT. For example, unauthorized people with ill-will can ably get access to government communication platforms and spread propaganda.

Second, a hacker can get unauthorized access to a warehouse containing explosive materials and program them to explode simultaneously. DeLoach opines that this can be catastrophic, especially if terrorists take advantage of the complexity of the Internet of Things.

Third is vulnerability; over the past few years, for example, organizations in the Internet of Things sector confident of their hitherto secure innovations have dared hackers to hack into their systems; the easiness with which the hackers did it questions the security of the systems.

Fourth, lack of privacy; the great quantity of data gathered through the Internet of Things innovations can easily lead to privacy intrusion. Fifth, there is the possibility of business rivalry among the companies providing IoT related services. Lastly, social media platforms can take advantage of the IoT to ignite uprisings.

To sum it up, there’s great unexploited potential in the IoT but stakeholders can be doomed and damned.

Self-Driving Cars: Save the Passenger and Run Over the Pedestrian?

The looming entry of emerging technologies like self-driving cars in the automotive industry will most likely reduce road fatalities but also poses a difficult moral dilemma. If your car has to make a choice, will it hit pedestrians on the road or veer off the road and put your life in danger?

The big challenge

An autonomous driving system requires programmers to develop an algorithm to make crucial decisions and funny enough, these will be based on ethics rather than on technology. According to a study, whose findings were released and published in the journal Science last week, figuring out how to build ethical self-driven cars is one of the biggest challenge in Artificial Intelligence.

Not all crashes can be avoided

With autonomous vehicles, you can expect a reduction in air pollution plus a host of other social benefits. In fact, the study was keen to point out that adoption of these cars will eliminate up to 89% of traffic accidents witnessed today. However, not all can be avoided. For instance, the autonomous vehicle (hereby abbreviated as an AV) may avoid hitting several pedestrians by swerving and hitting a passerby or it may be faced with the tough choice of sacrificing its own passenger in order to save the lives of many.

What’s your take?

When a number of people were asked about what they thought about AVs and the ethical decisions they had to make, they (people) responded in different ways. 3 in every 4 people said it would be more ethical for the car to sacrifice its passenger rather than hit 10 pedestrians. 19% said they would buy a self-driven car if it meant that a loved one might be sacrificed for the ‘greater good’. What’s your take on this? Do you think that regulation of the automotive industry with emphasis on autonomous vehicles will be the solution?

Big Data: From the Ground Up

To remain competitive in today’s technology-driven economy, companies have become more and more dependent on data. Whether a company uses data in decision-making is no longer the question. The popular buzzword “Big Data” echoed in both executive and operational corridors. Of course, many questions are raised about this term. To understand what Big Data is, one must strip off all the hype that makes it an enigma in the big digital world.

What is Big Data?

Big Data is a term that simply means an aggregate of all pieces of data that an organization has stored since its inception. There is a common misconception about Big Data – that it’s complex data collected somewhere, probably in a cloud and only savvy data scientists can access and manipulate it.

Big Data includes everyday sales data in a retail store, whether structured or unstructured. It might be on hardcopy invoices or stored in a digital form. Think of all the bookmarked URLs in each employee’s computer and data continually generated by the Internet of Things (IoT), websites, social media platforms, and other sources. That too is part of Big Data that can be used in different types of analysis to influence certain decisions.

Big Data at the bottom levels of an organization

Most employees at the operation level of an organization thing that Big Data is “a thing of the executives”. They don’t realize that they are the ones who create and interact with Big Data on a daily basis. Workers in low management levels ought to realize that every figure or statement they use and store in the company’s database forms part of the company’s Big Data. They, therefore, have a responsibility of ensuring data accuracy at the operational level.

Challenge to executives

Big Data has become the new reality of the corporate world. Management must know that the decisions it makes concerning data affect the reputation and ultimate valuation of the company. Companies are committing large amounts of resources on Big Data analytics. The use, misuse, and governance of data have a direct impact on the goodwill of the company.

Additive Manufacturing Creates Injectable Micro-camera

The world may be on the cusp of a biotech revolution after engineers from the University of Stuttgart designed a camera that is equivalent to the size of a grain of salt with the help of a new technology known as addictive manufacturing. This has the potential to change the landscape of health imaging as well as surveillance.

3D printing comes of age

3D Printing technology, also known as addictive manufacturing has been around for some time but is now starting to offer relevant solutions for practical problems. 3D printing technology can make three dimensional objects by depositing multiple layers of a particular substance according to the required shape and size. Researchers have managed to build a three lens camera using addictive manufacturing technology and fit it at the end of an optical fiber having a width of just two human hair strands. Such devices can be used extensive for exploring parts of the human body and organs which were earlier perceived as impossible.

Injectable camera can help monitor the brain

The device features a compound lens measuring 120 micro meters along with the casing and can be injected into the body using a syringe. The camera can easily focus on images from a distance of 3 mm and transmit the details over a 1.7 meter optical fiber cable attached to it. The lens can also be fitted to image sensors like the ones used in digital cameras.

Immense scope in medical and industrial applications

The minute size makes it ideal for non-destructive and non-invasive applications in both industry and healthcare. Manufacturing constraints have restricted the production of such tiny devices but all that could now change with the help of 3D printing technology. Researchers have revealed that it took only a few hours to design, manufacture and test the device and the results exceeded expectations. The lenses had tremendous compactness and delivered high performance. The lenses can also be deployed in clandestine surveillance by using them with security monitors and robots.

How Amazon Started the Robotic Arms Race

If you were to enter an Amazon warehouse, it is whirlwind of activity. You will come across workers everywhere piling items onto large black and yellow crates. Tall hydraulic arms haul heavy boxes to place them on rafters. What you may also see are a mass of chunky orange robots sliding along the floor, also stacked with boxes brimming with fashion to sports gear.

These are the very well-known Kiva robots, who once were an innovation that promised big things for the automation of inventory management. Amazon purchased their robot armies for w hopping $775 million in 2012. The acquisition elevated Amazon’s CEO Jeff Bezos to the head of an entire industry. He chose to reserve his robotics forces for the sole use of Amazon, effectively stopping Kiva from selling their products to warehouse operators and retailers who used this technology for speedy warehousing and distribution.

Since Kiva was the only player on the market, they were left with no choice. In the present environment, a few startups are gearing up to take off where Kiva left and arm warehouses around the world with new robotics. Amazon’s bots has already proved that robotic technology is indeed a better solution for the supply chain.

However, the new bots that are available look different, this could be attributed to the fact that it is still a nascent industry and partially due to patents. These bots can perform a wide variety of tasks like using mechanical claws to life items off shelves while others have touch screens for automated inventory checks. IAM Robotics’ Swift has been making waves. It is an autonomous mobile picking robot which comes equipped with a 3D item scanner and SwiftLink fleet management software.

Nevertheless, all of these bots are to aimed at fulfilling orders and to get your deliveries to your doorstep easy and quick.

Tiny Canadian Battery Company Could Play David to Goliath Tesla

Tesla Motors Inc., Panasonic Corp. and Samsung Electronics Co. are the giants who are battling it out in the race of mass producing large-scale rechargeable batteries. However, a tiny company may have hit the jackpot: Electrovaya Inc.

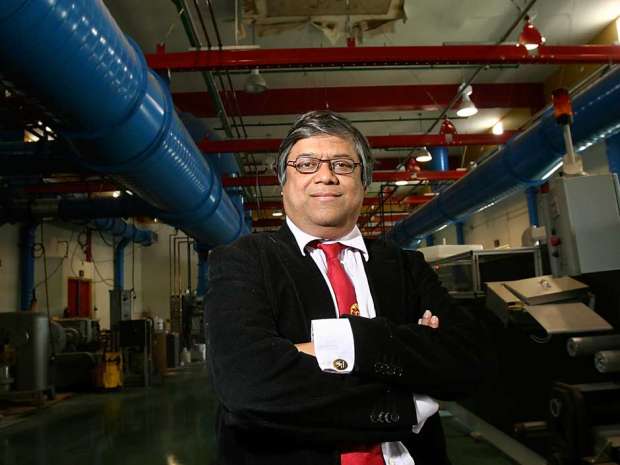

This Canadian company primarily manufactures lithium-ion batteries. It is owned and operated by an adjunct professor of electrochemistry at the University of Toronto. While the company’s portfolio might not seem impressive at first glance, investors are lining up at the door with Bloomberg New Energy Finance claiming its valuation at $250 billion by 2040.

Electrovaya’s shares have risen to five times their market value of C$297 million ($228.78 million) over the past 12 months. On the other hand, Tesla’s Powerwall failed to perform and they came down by 20%.

The company has risen at lightning speed, signing several deals worth millions of dollars. Electrovaya’s technology has 400 patents to its name and that is what gives the company its edge claims CEO Sankar Das Gupta. Not only is its flexible ceramic separator highly heat resistant, the company’s production processes are solvent-free which makes them greener for the environment and gives batteries double the life of a conventional one.

Indeed, the CEO claims to want to be the next General Electric. The small firm is taking on goliaths like Panasonic and Tesla, who are involved in joint product development. These two companies are involved in creating a $5 billion lithium-ion gigafactory in Nevada.

To finance their venture, the Canadian company has found some innovative solutions. It bought out Daimler AG’s lithium-ion battery manufacturing plant which was the largest in Europe. However, after the automaker decided to relinquish the business Electrovaya bought it at a fraction of its actual value.

This deal was also of utmost important due to the fact that it consisted of the factory’s proprietary ceramic separator technology. As the bane of a lithium-ion batteries is fire, the company seems to have made a strategic decision at the right time.

CEO Das Gupta claimed that the combination of German and Electrovaya technology will put them way ahead of Panasonic and Samsung. Today, the only competitor he sees is Polypore International Inc.’s lithium-ion separator. This company was acquired by Japan’s Asahi Kasei Corp. for $3.2 billion last year.

Beign a small company, Das Gupta says that the only problems he encounters is working capital. He hopes that the backing of Export Development Canada will help with the guarantee for lenders. While the company is the best bet in the energy equipment today, there’s no saying where the energy-storage marketplace tomorrow.