Big Data 2

Big Data: From the Ground Up

To remain competitive in today’s technology-driven economy, companies have become more and more dependent on data. Whether a company uses data in decision-making is no longer the question. The popular buzzword “Big Data” echoed in both executive and operational corridors. Of course, many questions are raised about this term. To understand what Big Data is, one must strip off all the hype that makes it an enigma in the big digital world.

What is Big Data?

Big Data is a term that simply means an aggregate of all pieces of data that an organization has stored since its inception. There is a common misconception about Big Data – that it’s complex data collected somewhere, probably in a cloud and only savvy data scientists can access and manipulate it.

Big Data includes everyday sales data in a retail store, whether structured or unstructured. It might be on hardcopy invoices or stored in a digital form. Think of all the bookmarked URLs in each employee’s computer and data continually generated by the Internet of Things (IoT), websites, social media platforms, and other sources. That too is part of Big Data that can be used in different types of analysis to influence certain decisions.

Big Data at the bottom levels of an organization

Most employees at the operation level of an organization thing that Big Data is “a thing of the executives”. They don’t realize that they are the ones who create and interact with Big Data on a daily basis. Workers in low management levels ought to realize that every figure or statement they use and store in the company’s database forms part of the company’s Big Data. They, therefore, have a responsibility of ensuring data accuracy at the operational level.

Challenge to executives

Big Data has become the new reality of the corporate world. Management must know that the decisions it makes concerning data affect the reputation and ultimate valuation of the company. Companies are committing large amounts of resources on Big Data analytics. The use, misuse, and governance of data have a direct impact on the goodwill of the company.

Top Megatrends in Manufacturing

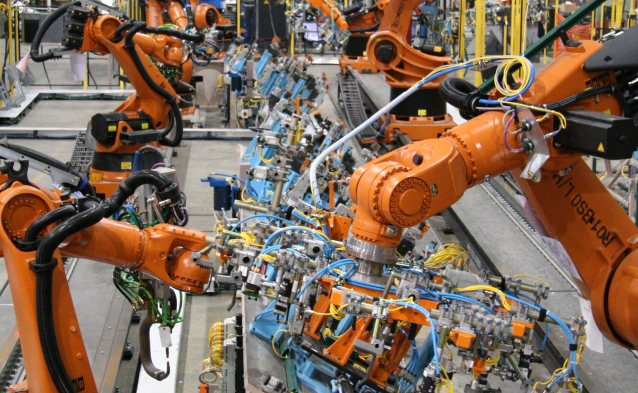

A new era has dawned in the manufacturing industry which is largely driven by digitalization, information technology and customization. These changes can be defined by several megatrends that are sweeping across the manufacturing footprint.

The pros and cons of the Digital Age

Information technology, along with other emerging technologies, are causing a dynamic and continuous change in the ways things get done. For example, smartphones today are miniaturized, have high processing capabilities and are way cheaper than their counterparts from the 60s.

On one hand while this can be a good thing, it also has the power to disrupt whole industries and reshape the workforce like the extinction of weavers and camera film makers.

But new technology and innovation brings with it new processes and advanced business models. For example, 3D printing is enabling the mass production and customization of products by small firms. Other emerging technologies to look out for include nanotechnology.

Big Data and Real-Time Information

The capacity to process large volumes of data for economic purposes has transformed customer care across retail and finance sectors. Big Data also plays a crucial role in manufacturing, with the fast-track incorporation of information technology. This will lead to more accurate forecasting and analysis of plant performance.

Big Data is buoyed by open platforms and crowdsourcing, which enable customer interaction like never before. The design, distribution and service is slated to get a complete overhaul with manufacturers becoming more knowledgeable.

Revolutionizing the workforce

The demographics of the workforce are rapidly changing with 10,000 baby boomers retiring each day. This is a cause of worry among manufacturers who see the institutional knowledge being lost and finding it hard to replace them with millennials who are disinterested in manufacturing jobs. Today, manufacturers are in dire need of a new wave of workforce that is equipped to work on the 21st-century shop floor.