Big Data: From the Ground Up

To remain competitive in today’s technology-driven economy, companies have become more and more dependent on data. Whether a company uses data in decision-making is no longer the question. The popular buzzword “Big Data” echoed in both executive and operational corridors. Of course, many questions are raised about this term. To understand what Big Data is, one must strip off all the hype that makes it an enigma in the big digital world.

What is Big Data?

Big Data is a term that simply means an aggregate of all pieces of data that an organization has stored since its inception. There is a common misconception about Big Data – that it’s complex data collected somewhere, probably in a cloud and only savvy data scientists can access and manipulate it.

Big Data includes everyday sales data in a retail store, whether structured or unstructured. It might be on hardcopy invoices or stored in a digital form. Think of all the bookmarked URLs in each employee’s computer and data continually generated by the Internet of Things (IoT), websites, social media platforms, and other sources. That too is part of Big Data that can be used in different types of analysis to influence certain decisions.

Big Data at the bottom levels of an organization

Most employees at the operation level of an organization thing that Big Data is “a thing of the executives”. They don’t realize that they are the ones who create and interact with Big Data on a daily basis. Workers in low management levels ought to realize that every figure or statement they use and store in the company’s database forms part of the company’s Big Data. They, therefore, have a responsibility of ensuring data accuracy at the operational level.

Challenge to executives

Big Data has become the new reality of the corporate world. Management must know that the decisions it makes concerning data affect the reputation and ultimate valuation of the company. Companies are committing large amounts of resources on Big Data analytics. The use, misuse, and governance of data have a direct impact on the goodwill of the company.

Additive Manufacturing Creates Injectable Micro-camera

The world may be on the cusp of a biotech revolution after engineers from the University of Stuttgart designed a camera that is equivalent to the size of a grain of salt with the help of a new technology known as addictive manufacturing. This has the potential to change the landscape of health imaging as well as surveillance.

3D printing comes of age

3D Printing technology, also known as addictive manufacturing has been around for some time but is now starting to offer relevant solutions for practical problems. 3D printing technology can make three dimensional objects by depositing multiple layers of a particular substance according to the required shape and size. Researchers have managed to build a three lens camera using addictive manufacturing technology and fit it at the end of an optical fiber having a width of just two human hair strands. Such devices can be used extensive for exploring parts of the human body and organs which were earlier perceived as impossible.

Injectable camera can help monitor the brain

The device features a compound lens measuring 120 micro meters along with the casing and can be injected into the body using a syringe. The camera can easily focus on images from a distance of 3 mm and transmit the details over a 1.7 meter optical fiber cable attached to it. The lens can also be fitted to image sensors like the ones used in digital cameras.

Immense scope in medical and industrial applications

The minute size makes it ideal for non-destructive and non-invasive applications in both industry and healthcare. Manufacturing constraints have restricted the production of such tiny devices but all that could now change with the help of 3D printing technology. Researchers have revealed that it took only a few hours to design, manufacture and test the device and the results exceeded expectations. The lenses had tremendous compactness and delivered high performance. The lenses can also be deployed in clandestine surveillance by using them with security monitors and robots.

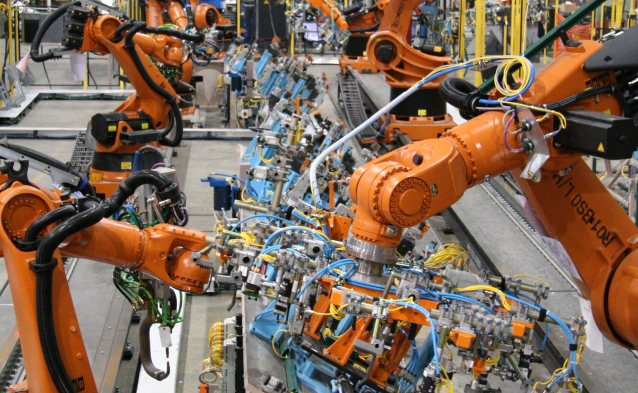

How Amazon Started the Robotic Arms Race

If you were to enter an Amazon warehouse, it is whirlwind of activity. You will come across workers everywhere piling items onto large black and yellow crates. Tall hydraulic arms haul heavy boxes to place them on rafters. What you may also see are a mass of chunky orange robots sliding along the floor, also stacked with boxes brimming with fashion to sports gear.

These are the very well-known Kiva robots, who once were an innovation that promised big things for the automation of inventory management. Amazon purchased their robot armies for w hopping $775 million in 2012. The acquisition elevated Amazon’s CEO Jeff Bezos to the head of an entire industry. He chose to reserve his robotics forces for the sole use of Amazon, effectively stopping Kiva from selling their products to warehouse operators and retailers who used this technology for speedy warehousing and distribution.

Since Kiva was the only player on the market, they were left with no choice. In the present environment, a few startups are gearing up to take off where Kiva left and arm warehouses around the world with new robotics. Amazon’s bots has already proved that robotic technology is indeed a better solution for the supply chain.

However, the new bots that are available look different, this could be attributed to the fact that it is still a nascent industry and partially due to patents. These bots can perform a wide variety of tasks like using mechanical claws to life items off shelves while others have touch screens for automated inventory checks. IAM Robotics’ Swift has been making waves. It is an autonomous mobile picking robot which comes equipped with a 3D item scanner and SwiftLink fleet management software.

Nevertheless, all of these bots are to aimed at fulfilling orders and to get your deliveries to your doorstep easy and quick.

Cornell Study Shows Women Behind on Skill Training

In working-class towns, men find it easy to join the workforce as manual laborers and machinists. Cornell university research shows that the wide pay gap and lack of work pushes women out of blue-collar jobs.

Vocational education schools versus prep courses for college showed a male preference for vocational training, and therefore, a greater likelihood to find better-paid blue-collar jobs upon graduation, shows the Cornell study published in the American Sociological Review.

Touching upon the pay gap for women in blue-collar jobs – it can be as high as 22% less than their male counterparts. This is a significantly wider gap than that in white-collar jobs or service-industry positions shows the same study. The gender gap in employment and wages was more prominently visible in young people from blue-collar communities who completed high school.

In many ways, blue-collar jobs are still just as biased towards men as they were in the 50s. The condition of the female workforce in towns where jobs are mostly concentrated on construction and manufacturing is sharply distinguished from that of women over the U.S. generally, where women have a greater likelihood for going to college than men.

These communities are struggling to fill in the large amount of production jobs that need to be filled. More than 3.5 million vacancies across the U.S. have been estimated over the next 10 years. The present lack of skilled labor could cause a deficit in filling 2 million of those positions, as was predicted by Deloitte and the Manufacturing Institute.

This shows the need for educators to actively address these gender issues in discussions about vocational training while paving the way for college. Today, statistics show a preference for skilled jobs over advanced math. While men can definitely benefit from college prep classes, encouraging women to opt for vocational courses can do much for the economy in the future.

What is the Real Challenge with Omnichannel?

A study conducted by JDA shows that 71% of CEOs consider omnichannel fulfillment to be the future of the consumer goods industry. However, only 19% are able to profitably translate this vision into reality.

Why the supply chain is top priority

Findings have shown that consumers are induced to buy when offered seamless shipping, delivery and returns. These are the key factors that drive the growth strategies of e-commerce ventures. Following these findings, fulfillment has gone to the top of retailers’ lists, with merchants investing in transportation and logistics, delivery options, order management, inventory and returns management.

Regular online shoppers want a turbo-charged supply chain

Free shipping remains the most lurid reason, with nine out of ten shoppers claiming that to be the incentive for shopping online. Over time, this has become the singular most powerful objective for retailers over other logistics concerns, even same-day shipping gained brownie points. One-day shipping (69%) and free returns (68%) are also top persuasive factors for shoppers.

Bringing together in-store and online experiences

While e-commerce is obviously an integral part of our lives, studies show that shopping in brick-and-mortar stores remains a clear preference, though some shoppers showed an openness to a blended shopping experience with physical and online shopping.

Although beacons have had a slow start, there is no mistaking that shoppers might be incentivized to the concept of the in-store experience online, virtual reality e-commerce – or v-commerce.

Sluggish adoption of mobile payments

Privacy and security are the key areas where consumers back off in using mobile payment applications. A greater change in consumer behavior is needed to make mobile payment transactions easier and profitable.

In time, consumer behavior and technology will need to be integrated for a more practical approach to e-retail.

Top Megatrends in Manufacturing

A new era has dawned in the manufacturing industry which is largely driven by digitalization, information technology and customization. These changes can be defined by several megatrends that are sweeping across the manufacturing footprint.

The pros and cons of the Digital Age

Information technology, along with other emerging technologies, are causing a dynamic and continuous change in the ways things get done. For example, smartphones today are miniaturized, have high processing capabilities and are way cheaper than their counterparts from the 60s.

On one hand while this can be a good thing, it also has the power to disrupt whole industries and reshape the workforce like the extinction of weavers and camera film makers.

But new technology and innovation brings with it new processes and advanced business models. For example, 3D printing is enabling the mass production and customization of products by small firms. Other emerging technologies to look out for include nanotechnology.

Big Data and Real-Time Information

The capacity to process large volumes of data for economic purposes has transformed customer care across retail and finance sectors. Big Data also plays a crucial role in manufacturing, with the fast-track incorporation of information technology. This will lead to more accurate forecasting and analysis of plant performance.

Big Data is buoyed by open platforms and crowdsourcing, which enable customer interaction like never before. The design, distribution and service is slated to get a complete overhaul with manufacturers becoming more knowledgeable.

Revolutionizing the workforce

The demographics of the workforce are rapidly changing with 10,000 baby boomers retiring each day. This is a cause of worry among manufacturers who see the institutional knowledge being lost and finding it hard to replace them with millennials who are disinterested in manufacturing jobs. Today, manufacturers are in dire need of a new wave of workforce that is equipped to work on the 21st-century shop floor.

Is This the End of Chinese Manufacturing?

A Chinese financial magazine Caixin Purchasing Managers’ Index along with data complier Markit claimed that trade came in at 48.6 in June, down from 49.2 in May. These numbers seem to spell a stoppage in the flow as global economy deteriorates.

Manufacturers seem to be giving out more pink slips for the third year in a row, Caixin claimed, in a bid to curb costs in the face of a plunging demand. Caixin says that the government must work towards reinforcing its proactive fiscal policy while a prudent monetary policy should continue to be used as a shield against a choppy external economic environment.

With everyone looking to China as one of the key players in global expansion, its economy only grew 6.9% last year, its weakest rate in 25 years. The manufacturing sector seems to be burdened with excess industrial capacity from its prosperous infrastructure-building days.

Growth of Euro-area manufacturing in 2016

In the face of China’s slump, Euro-area manufacturing seems to have taken off. The PMI in Europe rose from 51.5 to 52.8. While these numbers can see a change with the onset of Brexit. Short-term consumer habits may undergo a change with Brexit. The good is though, studies by Eurostat show a rise in employment that is the highest in five years.

Euro-area factory growth was pioneered by Germany and Austria, and expansion was also visible in Spain, Ireland and Italy. Greece also showed signs of growth.

Russia welcomes growth

Russia has seen the greatest growth so far, with its manufacturing industry driven by domestic demand. Russia’s Purchasing Manager’s Index swelled to 51.5 in June from 49.6 in May. This figure has bettered all expert forecasts and is a positive sign for the country’s economy.

Tiny Canadian Battery Company Could Play David to Goliath Tesla

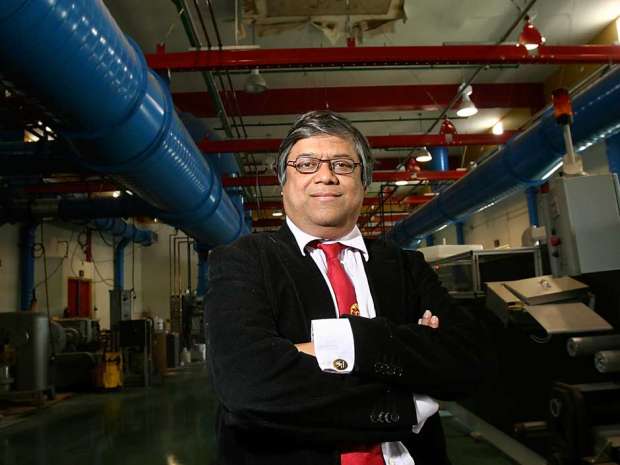

Tesla Motors Inc., Panasonic Corp. and Samsung Electronics Co. are the giants who are battling it out in the race of mass producing large-scale rechargeable batteries. However, a tiny company may have hit the jackpot: Electrovaya Inc.

This Canadian company primarily manufactures lithium-ion batteries. It is owned and operated by an adjunct professor of electrochemistry at the University of Toronto. While the company’s portfolio might not seem impressive at first glance, investors are lining up at the door with Bloomberg New Energy Finance claiming its valuation at $250 billion by 2040.

Electrovaya’s shares have risen to five times their market value of C$297 million ($228.78 million) over the past 12 months. On the other hand, Tesla’s Powerwall failed to perform and they came down by 20%.

The company has risen at lightning speed, signing several deals worth millions of dollars. Electrovaya’s technology has 400 patents to its name and that is what gives the company its edge claims CEO Sankar Das Gupta. Not only is its flexible ceramic separator highly heat resistant, the company’s production processes are solvent-free which makes them greener for the environment and gives batteries double the life of a conventional one.

Indeed, the CEO claims to want to be the next General Electric. The small firm is taking on goliaths like Panasonic and Tesla, who are involved in joint product development. These two companies are involved in creating a $5 billion lithium-ion gigafactory in Nevada.

To finance their venture, the Canadian company has found some innovative solutions. It bought out Daimler AG’s lithium-ion battery manufacturing plant which was the largest in Europe. However, after the automaker decided to relinquish the business Electrovaya bought it at a fraction of its actual value.

This deal was also of utmost important due to the fact that it consisted of the factory’s proprietary ceramic separator technology. As the bane of a lithium-ion batteries is fire, the company seems to have made a strategic decision at the right time.

CEO Das Gupta claimed that the combination of German and Electrovaya technology will put them way ahead of Panasonic and Samsung. Today, the only competitor he sees is Polypore International Inc.’s lithium-ion separator. This company was acquired by Japan’s Asahi Kasei Corp. for $3.2 billion last year.

Beign a small company, Das Gupta says that the only problems he encounters is working capital. He hopes that the backing of Export Development Canada will help with the guarantee for lenders. While the company is the best bet in the energy equipment today, there’s no saying where the energy-storage marketplace tomorrow.